HYAERO Vacuum Rinser

HYAERO Vacuum Rinser

HYSEKAM Can Technology

HYAERO Vacuum Rinser

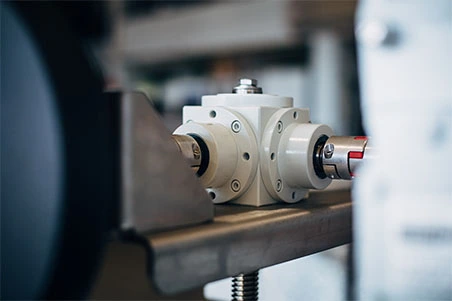

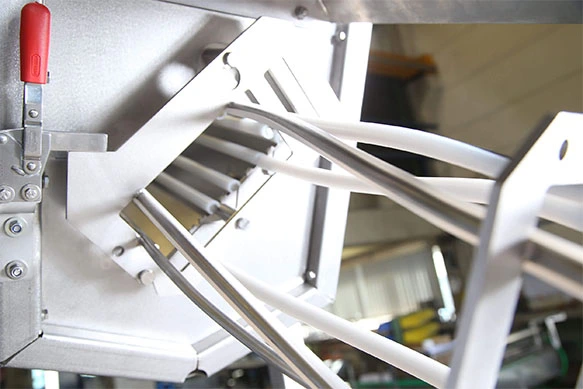

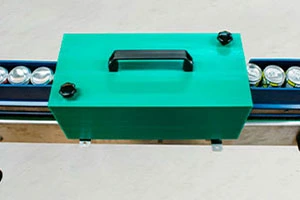

With our HYAERO Vacuum Rinser, the cans are sucked into the perforated flat top chain using a vacuum applied inside and rinsed out with water or ionized air after a 180 ° rotation around the rinser. The HYAERO Vacuum Rinser has a modular structure with a predefined entry and outlet as well as variable segments. The advantage of the HYAERO Vacuum Rinser is that different can formats can be processed without having to modify the vacuum generation system, which means that additional modification costs for format sets are eliminated.

The development of the HYAERO Vacuum Rinser is a project funded by the Federal Ministry of Economics and Energy (BMWi).

Technical Data of our HYAERO Vacuum Rinser

- Power up to 120,000 cans per hour (excluding a power reserve)

- Inlet and outlet adaptable to the existing line

- Processing of beverage cans in all common dimensions (larger volumes on request)

- Can be used in the food, cosmetics and pharmaceutical industries

Options for the HYAERO

- Ionizing unit

- 3 stage HEPA filter

- Water spray zone instead of the ionization unit

- Electrical control

Advantages of HYAERO over classic gravity rinser

- No risk of can damage, as the cans are absorbed from the vacuum after the inlet transfer station and transported with a vacuum to the outlet transfer station

- Power up to 120,000 doses per hour (excluding a power reserve)

- Easy integration of the system into transport control

- If necessary, it is possible to run with gaps

- No new costs when extending the line with additional cans, as all can formats can be driven through the vacuum without conversions

- Independent of different can paints, as the vacuum does not result in mechanical friction

HYTRANS Vakuumbrücke

HYTRANS Massen-Vakuumbrücke

HYTRANS einspurige Vakuumbrücke

HYVAC Vakuum Transporteur

HYWHEEL Vakuum Codierstern

HYJET Rinser

Stangenrinser

HYAERO Vakuumrinser

HYTWIST Produktwender

HYTWIST Blockwender 450

HYTWIST Stangenwender 1230

HYTWIST Dosenwendestation

HYROPE Seiltransport

HYFLEX Vollautomatischer Dosenwender