HYTRANS Vacuum Bridges

HYTRANS Vacuum Bridges

HYSEKAM Can Technology

HYTRANS Vacuum Bridges

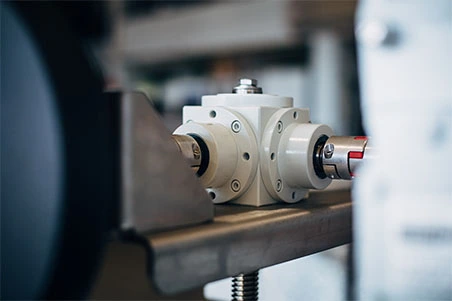

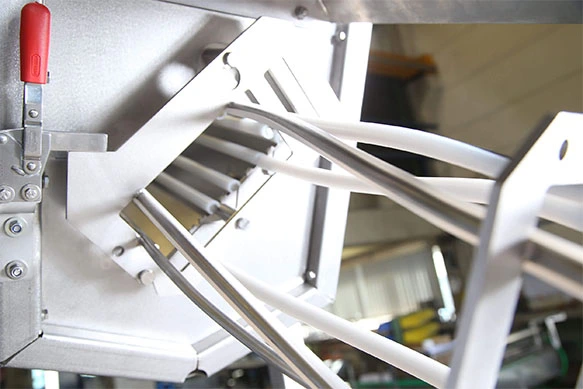

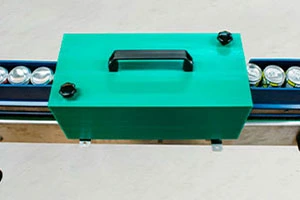

The HYTRANS Single-Track Vacuum Bridge and the HYTRANS Mass Vacuum Bridge are fully automatic can converters suitable for processing all common empty can sizes and types made of aluminum, steel and plastic. The central stepless height adjustment, which can be changed either semi-automatically by hand wheel or fully automatically, allows a quick and easy adjustment of the machine for smooth processing of the commercially available can sizes. In addition, the HYTRANS Vacuum Bridges offer easy operation and generous access during conversion and maintenance work. Both models can be used in the beverage, food, cosmetics and pharmaceutical industries.

The Respective Function of the Two Vacuum Bridges

The single-lane vacuum bridge is used for empty can coding and coding inspection.

The function of the mass vacuum bridge is to eject cans that are lying flat or severely deformed.

HYTRANS Vakuumbrücke

HYTRANS Massen-Vakuumbrücke

HYTRANS einspurige Vakuumbrücke

HYVAC Vakuum Transporteur

HYWHEEL Vakuum Codierstern

HYJET Rinser

Stangenrinser

HYAERO Vakuumrinser

HYTWIST Produktwender

HYTWIST Blockwender 450

HYTWIST Stangenwender 1230

HYTWIST Dosenwendestation

HYROPE Seiltransport

HYFLEX Vollautomatischer Dosenwender