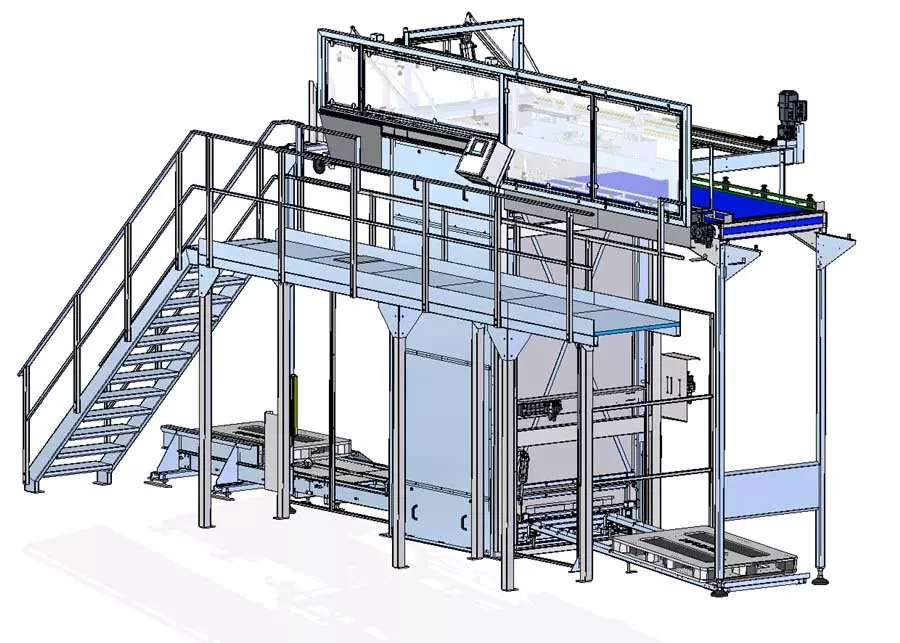

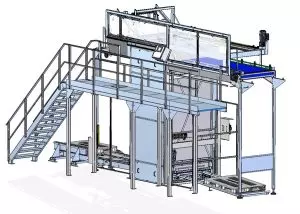

Fully automatic depalletizer with pallet stacking magazine and cover frame removal

Depalletizer

Fully automatic depalletizer with pallet stacking magazine and cover frame removal

The fully automatic depalletizer depalletizes almost all cylindrical and square empty containers such as beverage cans, food cans, bottles (glass). The system of the fully automatic depalletizer is suitable up to a capacity of 60,000 cph.

Technical specifications

- Types of containers: cans and bottles (after checking the container and intermediate layer

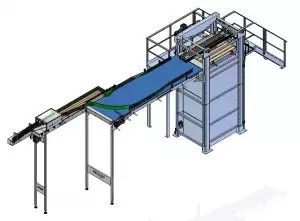

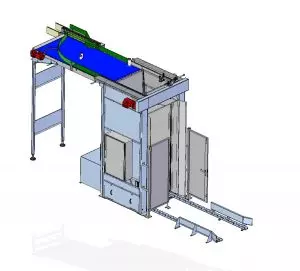

- Performance range up to 60,000 cph, 10 meter feed table (divided with 2 drives) and multi-lane separation with oscillating guide

- Executions:

- Pushing off only linearly on the loading table is possible

- Feed table 10 m at least 2 drives (width approx. 1,200 mm)

- Multi-lane separation (approx. 5 m), left, right and linear installationr

- Depalletizing shaft in painted design, including control cabinet and control

- Base frame: approx. 1,800 mm wide x 2,300 mm long

- Push-off height: 3,000 mm, total height: approx. 4,250 mm

- Push-off height: 3,500 mm, total height: approx. 4,750 mm

- Push-off height: 4,000 mm, total height: approx. 5,250 mm

- Other push-off heights on request

- Pallet chain conveyor (wrapping, double provision, lifting shaft) + 300mm

- Chain conveyor with empty pallet stacking magazine behind the shaft

- Shaft for intermediate layers: Above the provision at push-off height

- Intermediate storage for interlayer change (pallet)

- Automatic interlayer removal using negative pressure

- Upper pusher frame adjustable by hand in stainless steel

- Hoist: Electromechanical chain lift

- Pusher: Electromechanical chain drive

- Pallet sizes: min. 1200 mm long x 1000 mm wide; Max. 1420 mm long x 1250 mm wide

- Cover frame removal: Automatic (cover frame is returned to the empty pallet)

- Access protection: Depalletization shaft in the inlet area with protective fence and light strip monitoring

- Pallet change approx. 20 – 40 seconds (depending on the push-off height)

- Buffer area depends on the line output (Ø66 approx. 250 cans / m²)

- Platform with stairs

- Electrical control according to MEYER standard

Mikrobrauerei Depalettierer

Manueller Handabschieber

Motorische unterstützter Abschieber

Automatischer Depalettierer

Vollautomatischer Depalettierer mit Palettenstapelmagazin und Deckrahmenentnahme

Depalettierer mit variabler Abschiebehöhe

Vakuum-Depalettierer