HYSTERIL Headspace Sterilizer (Glass & PET Bottles)

HYSTERIL Headspace Sterilizer (Glass & PET Bottles)

HFM Special Engineering

HYSTERIL Headspace Sterilizer (Glass & PET Bottles)

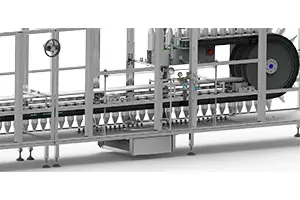

Our HYSTERIL Headspace Sterilizer (Necksterilizer) is used to rotate filled reusable and disposable bottles in order to disinfect the headspace of the bottles. The headspace sterilizer impresses with its modular construction system in stainless steel, which offers the possibility of a product-dependent sterilization length and time. The sterilization path can be extended in segments of 2000 or 3000 mm up to a maximum length of 30.2 m. In addition, the number of degrees of the turn and the type of sterilization – hot or cold – can be adjusted according to customer-specific needs.

Positive Property of the Hysteril Headspace Sterilizer / or Advantages of our High-Quality Product

The Headspace Sterilizer is able to sterilize reusable and disposable bottles of all sizes made of glass and PET from the food, cosmetics and pharmaceutical industries. The product impresses with its simple operation and generous access during conversion and maintenance work. Great importance is attached to container conveying that is extremely gentle on the product, which is characterized, among other things, by container-dependent floor cooling (nitro hotfill if required). The machine also includes a continuous light barrier-secured protection concept. The bottles can be fed in from either the left or the right. Further advantages of the headspace sterilizer are floor cooling, accessibility from both sides over the entire system, a central drive for the sterilization chain, as well as the integrated chain tensioning, cooling and cleaning.

Technical Data of our Headspace Sterilizer

- Processing of all standard reusable and non-returnable bottles made of glass and PET from the pharmaceutical, cosmetic and food industries. (max. height 340 mm)

- Easy to clean, hygienic design

- The modular system enables the sterilization length to be adjusted according to customer requirements, depending on the product – this can be extended seamlessly with 2000 and 3000 mm extension units. Extension up to max. Sterilization distance of 30.2 meters.

- Extremely gentle container conveyance through special chains

- Infinitely variable turning curve of the sterilization chain for a harmonious turning process

- The head sterilizer has an integrated chain tensioning and cooling system. Central drive for the sterilization chain is available

- There is a continuous, closed protection concept, which consists of a light barrier secured access to the interior (with immediate stop)

- Safety jam switch against backflow wedging at the container outlet

- Function: tank inlet

- Infeed chain for infeed and container bottom support when turning

- Containers can be turned by 100 ° (possible up to 120 ° without conversion) from the standing position to the lying sterilization position

- Turning through a synchronous, continuous twisting of the turning chain and the sterilization chain, which run at right angles to each other in the turning area

- Sterilization chain for container transfer to the sterilization area

- Function: container outlet

- Turning back through a synchronous, continuous twisting of the sterilization chain and the turning chain, which run at right angles to each other in the turning area

- Containers can be turned back by 100 ° (possible up to 120 ° without conversion) from the horizontal sterilization position to the standing discharge position

- Outlet chain for container bottom support when turning back and conveying away

- Sterilization chain for transfer from the sterilization area

- Standard efficient bevel geared motor and SEW MOVIEGEAR® drives

Beer Table Set Washing System

HYAERO M Blow-out Station

HYLIGHT

Bottle Rinser