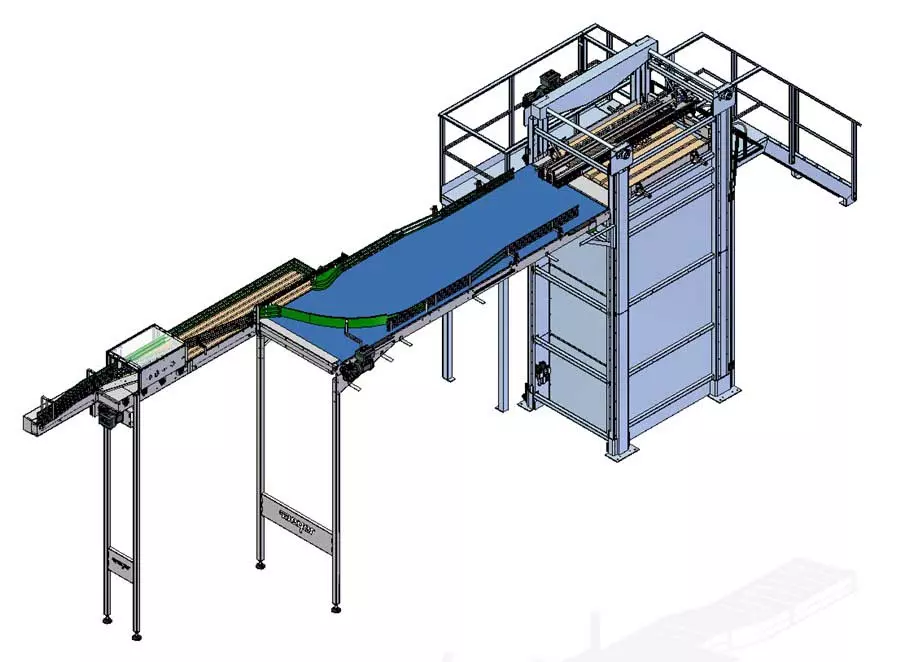

Microbrewery Depalletizer

Depalettizer

Microbrewery Depalletizer

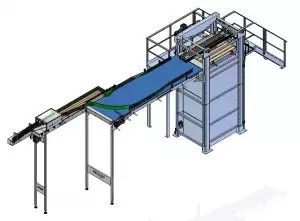

The pusher, specially designed for craft / microbreweries, depalletizes cans up to max. 24,000 cph. It was precisely tailored to the needs of small breweries, is cost-effective, the cans can be pushed off on all sides and can be modularly adapted to different conditions.

Technical Data of our Microbrewery Depalletizer

- Types of packaging: cans

- Power:

- Performance range up to 9,000 cph without a feed table with single-lane separation.

- Performance range up to 24,000 cph, 4.5 meter feed table and multi-lane separation with oscillating guide

- Executions:

- 4 push-off sides possible

- with feed table up to 4.5 m in length, depending on performance

- single-lane separation (4 m), installation left and right

- multi-lane separation (approx. 5 m), left, right and linear installation

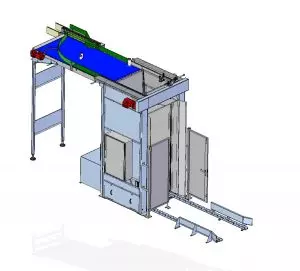

- Depalletizing shaft in painted design, including control cabinet and control

- Base frame: approx. 1,400 mm wide x 1,940 mm long

- Total shaft height: approx. 4,300 mm

- Push-off height: 3,500 mm

- Shaft for intermediate layers: approx. 1550mm wide x 400mm long x 2,750mm high

- Interlayer removal:

- Standard: Automatic interlayer removal (pneumatic with vacuum suction device)

- Upper pusher frame adjustable on one side by hand in stainless steel

- Hoist: Electromechanical chain lift (gear motor)

- Pusher: Electromechanical with spindle (stepper motor)

- With push-off direction left and right, the intermediate layers are collected in a shaft on the side of the door, with linear push-off direction in a shaft on the door

- Cover frame removal: manually – in front of the shaft

- Access protection: Depalletization shaft above door with locking function

- Default time for pallet change 2 minutes / buffer time

- Buffer area

- approx. 1.2 m² buffer area at 9,000 cph with single-lane separation 4 meters long

- approx. 3.5 m² buffer area at 24,000 cph = feed table 4.5 meters long

- Pallet sizes: min. 1200 mm long x 1000 mm wide, max. 1420 mm long x 1250 mm wide

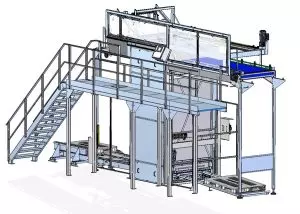

Options

- Intermediate layer shaft with feed for storage on pallet

- Pedestal with ladder

- Platform with stairs including platform for cover frame removal

Mikrobrauerei Depalettierer

Manueller Handabschieber

Motorische unterstützter Abschieber

Automatischer Depalettierer

Vollautomatischer Depalettierer mit Palettenstapelmagazin und Deckrahmenentnahme

Depalettierer mit variabler Abschiebehöhe

Vakuum-Depalettierer