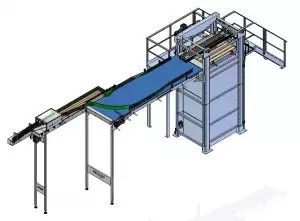

Manual hand pusher

Depalletizer

Manual hand pusher

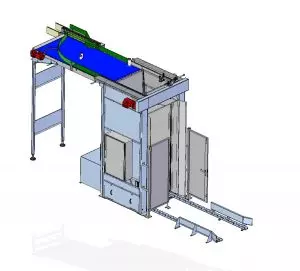

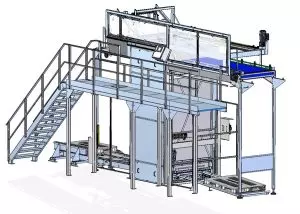

The manual pusher depalletizes various cans. The system is suitable for up to 30,000 cans per hour (cph). The introduction of the can pallet into the shaft, the removal of the intermediate layers and the pushing off must be carried out manually. Due to the modular and flexible design, various options can be used to expand the system.

Technical data of our manual slide valve

- Container type: cans

- Performance range up to 30,000 cph, with feed table and multi-lane separation with oscillating guide (this performance depends on the operator)

- Executions:

- Pushing off only linearly on the loading table is possible

- Feed table from 3 m length (width approx. 1,200 mm)

- multi-lane separation (approx. 5 m), left, right and linear installation

- Default time for pallet change 1.5 minutes / buffer time

- Buffer area depends on the line output Ø66 approx. 250 cans / m²

- Depalletizing shaft in painted design, including control cabinet and control

- Base frame: approx. 2,150 mm wide x 1,500 mm long

- Total shaft height: approx. 4,100 mm

- Push-off height: 3,480 mm

- Shaft for intermediate layers: approx. 1550mm wide x 200mm long x 2.750mm high

- Feeding of the pallets via gravity roller conveyor

- Interlayer removal: manually

- Hoist: Electromechanical chain lift

- Pusher: Manual pusher bar

- Cover frame removal: manually – in front of the shaft

- Access protection: depalletizing shaft above door with safety switch

- Platform with stairs including platform for cover frame removal

- Pallet sizes: max. 1420 mm long x 1250 mm wide

- Electrical control according to MEYER standard

Manual hand slide options

- Intermediate layer shaft on the platform with manual emptying

- second pallet format possible after testing

Mikrobrauerei Depalettierer

Manueller Handabschieber

Motorische unterstützter Abschieber

Automatischer Depalettierer

Vollautomatischer Depalettierer mit Palettenstapelmagazin und Deckrahmenentnahme

Depalettierer mit variabler Abschiebehöhe

Vakuum-Depalettierer