Cage Rinser

Cage Rinser

HYSEKAM Can Technology

Cage Rinser

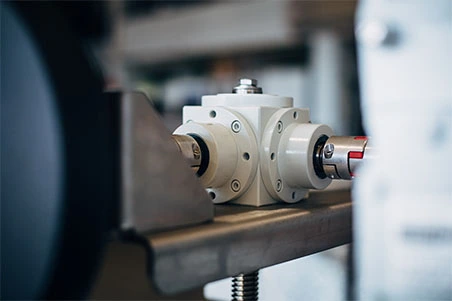

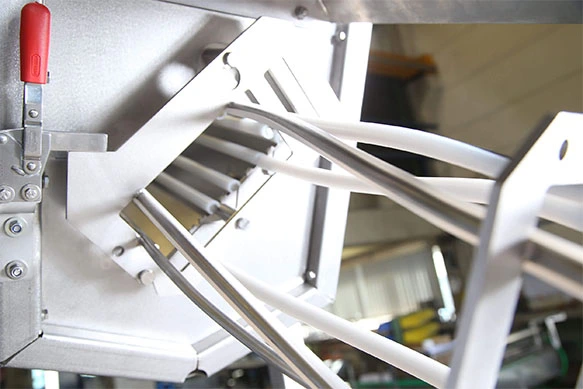

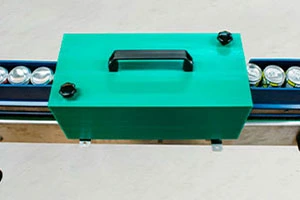

With the cage rinser, it is possible to clean cans either by means of water (HYJET) or ionized air (HYION). Our machine has been designed so that all beverage cans can be processed with the usual dimensions. For the different dose sizes, only a manual replacement of the inlet and outlet heads is necessary. The modular principle was used for the construction, whereby the standard inclination of this rinser is 30°. For easy access to the entire channel length, the cage rinser has a hinged PETG or stainless steel hoods, depending on the version.

Technical Data for the Cage Rinser

- High cleaning performance with up to 120,000 products per hour

- Hinged PETG or stainless steel hoods allow easy access to the entire channel length

- Easy-to-clean, hygienic design

- Height adjustment semi-automatically by handwheel or fully automatic. The diameter is adjusted manually

- Further options of a HYJET (water) rinser: Use of additional cleaning media (hot water or steam), integration of water reuse (tank) and “clean in place” piping

- The standard HYION air rinse can be extended by a further blow-out.

- Rope and chain transports can be used as compatible transport systems

- Can be used in the food, cosmetics and pharmaceutical industries

- Modular building block system

- Processing of beverage cans in all common dimensions (larger volumes on request)

Options for the Block and Cage Rinsers

- Execution of inlet, outlet and rinsing channel

- Covers for inlet and outlet

- Side curtains over the entire canal

- Water collecting tray at the outlet

- Format changes (height and diameter) possible

- Printing support

- Air support in the inlet

- Funding aid in the rinser

- Pre-filter for blower (G4)

- Water treatment (HYJET)

- Pre-filter for fresh water connection

- Pressure sensors

- Flow meter

- Temperature sensor

- CLO2 sensor including evaluation unit

- Liquid Detection

- Tank

- Tank extensions

- Filter units and sensors for tanks

- Endress + Hauser flow meter in the main supply line

- Water inlet for tank

- Safety switch

- Piping for water inlet

- CIP piping + safety

- V4A / 1.4401 / 1.4571 / version (CIP, CLO2)

- Blow-out (HYION)

- Blow-out zone with side channel compressor instead of compressed air

- Ionizing unit

- Second rins zone with side channel blower

- F7 / F9 filter exhaust zone 1 and / or 2

- 3-stage HEPA filter blow-out zone 1 and / or 2

- Extraction radial fan or Blotenberg

- Filters for suction

- Pressure sensors for nozzle holder

- Flow sensor at the end of the nozzle assembly

- Fully automatic rinser adjustment with SIKO drives

- Coding: Mechanical interface for encoder integration

- Additional covers

- Window in Rinsing pan

- Fully automatic rinser adjustment with SIKO drives

- Various control cabinets

- TWIN version

- Additional HYCOMI, after a TWIN rinser, guides the empty cans from two lanes together onto one lane

- Automatic diameter adjustment

- Automatic height adjustment

- Electrical integration in rinser control

- HYRACKS – brackets for bar turner

- Floor or wall mounting – or in a rolling version

- Electric control

Stangenrinser

HYTRANS Vakuumbrücke

HYTRANS einspurige Vakuumbrücke

HYVAC Vakuum Transporteur

HYWHEEL Vakuum Codierstern

HYJET Rinser

HYTRANS Massen-Vakuumbrücke

HYAERO Vakuumrinser

HYTWIST Produktwender

HYTWIST Blockwender 450

HYTWIST Stangenwender 1230

HYTWIST Dosenwendestation

HYROPE Seiltransport

HYFLEX Vollautomatischer Dosenwender